The rapid transformation of the energy and transport sectors, especially in battery production often exposes the contradiction between a “green” future and the practical challenges of large-scale industrial operations. How sustainable are battery factories in reality, when their operation also brings significant environmental and social costs? Below, we examine this duality: the key environmental impacts, the health and social concerns, and several positive European examples viewed through the lens of the EU’s Fit for 55 objectives.

Environmental Impacts

Water and energy use, waste, and local ecosystems

Large-scale lithium-ion battery factories require substantial water, energy, and raw materials, while generating industrial waste and posing risks to neighbouring ecosystems.

According to a study prepared for the European Parliament, the life-cycle environmental impacts of lithium-ion batteries including production, depend strongly on the carbon intensity of electricity generation and raw-material extraction. European Parliament

The EU Battery Regulation requires manufacturers to monitor and report the carbon footprint of batteries across all stages of production, use, and recycling expressed as kg CO₂-eq per kWh of capacity. Battery Regulation

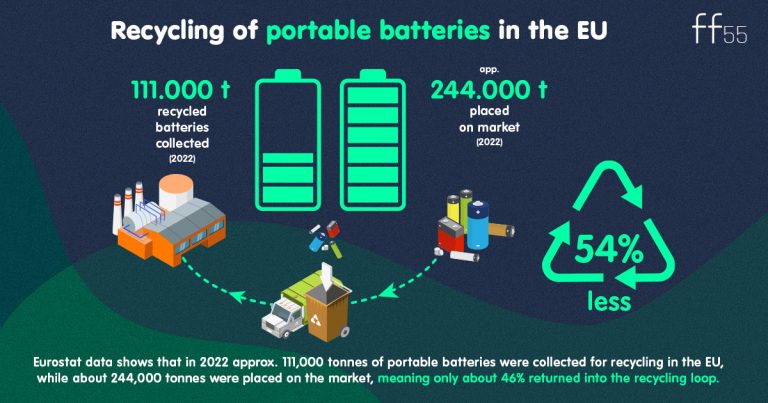

Eurostat data shows that in 2022 approx. 111,000 tonnes of portable batteries were collected for recycling in the EU, while about 244,000 tonnes were placed on the market, meaning only about 46% returned into the recycling loop.

Although detailed water-use data of specific plants is rarely public, it is well-known that battery factories require large quantities of water for cooling, climate-control, and chemical processes. Local impacts may include reduced water availability, heat discharge, noise, or increased road traffic. A major battery plant may generate hundreds of truck movements per day, contributing to air and noise pollution.

If plants are located near forests, wetlands, or sensitive ecosystems, land conversion, soil disturbance, and potential chemical leakage also pose risks. The carbon footprint of production strongly depends on the local energy mix: facilities running on fossil-based electricity inherently produce higher emissions. Transport & Environment

In short: the battery industry is a key component of the green transition, but it is not automatically green. Energy use, water demand, waste management, logistics, and land-use impacts all shape whether a factory becomes a sustainable solution or a grey compromise.

Health and social concerns

Public resistance, transparency, and community engagement

Alongside environmental impacts, battery factories raise several social and health-related concerns. In many regions, residents express worries about noise, traffic, air quality, and the handling of chemicals used in cell production.

Transparency plays a crucial role. Communities often demand not only compliance with regulations but proactive communication about emissions, waste-handling, and emergency procedures. Mineral Group

An example: in Finland, a planned cell-production project includes public forums as part of its Environmental Impact Assessment (EIA) process.

Potential health risks include exposure to solvents, electrolytes, or airborne particles if accidents or improper handling occur. While modern plants significantly mitigate such risks, community concerns often intensify when residents feel excluded from decision-making. HSE

On the social side, large investments often raise expectations about job creation and long-term economic growth. However, if projects are delayed or downscaled, local dissatisfaction may rise. Questions frequently asked by residents include:

- What will happen to the plant in 20–30 years?

- How will waste and recycling be managed?

- What guarantees exist for environmental safety?

Meaningful community engagement is therefore essential for long-term acceptance. EBA

Positive European examples:

Finland:

In the Kotka-Hamina region, a planned cell plant would produce up to 60 GWh of battery cells annually, enough for more than one million electric vehicles. Kotka

Finland’s relatively low-carbon electricity mix (hydropower, nuclear) and strong EIA processes help reduce the environmental footprint. The Finnish battery industry also emphasises transparency and responsible sourcing. Science Direct

France

France is building a “Battery Valley” in the Hauts-de-France region. As of 2023, two plants were operational and four more under construction. The strategy includes not only manufacturing but also recycling and raw-material processing. Mobility Portal

A notable example: LG Energy Solution and Derichebourg are launching a joint venture capable of recycling more than 20,000 tonnes of battery waste annually. Electrive

Sweden

Sweden hosts some of Europe’s most sustainability-focused battery factories. Northvolt’s Skellefteå plant, for instance, operates near hydropower and wind-energy sources, significantly reducing production emissions.

Although challenges remain (energy supply, raw-material sourcing), the Swedish model shows that genuinely low-carbon battery production is achievable. Business Sweden, Le Monde

Green industry or grey compromise?

The analysis shows a complex picture. While battery factories can support the green transition, they may still carry considerable environmental and social burdens. The EU’s Fit for 55 package aiming for at least 55% reduction in net greenhouse-gas emissions by 2030 compared to 1990 makes it clear that every sector, including battery manufacturing, must contribute. European Parliament

To be “Fit for 55,” factories must operate with low-carbon electricity, minimize water and material use, ensure responsible sourcing, increase recycling, and involve local communities transparently. Otherwise, even a facility supporting electric-vehicle production may represent a grey compromise rather than a truly green industrial shift.

Industry groups also highlight that cooperation between policymakers and manufacturers is essential to align battery production with emission-reduction goals. Eurobat, Science Direct

Conclusion

Battery manufacturing is indispensable for Europe’s energy and transport transition. Yet, without responsible water, energy, and waste-management practices and without strong community engagement factories risk creating new environmental and social tensions.

Positive cases in Finland, France, and Sweden demonstrate that smarter, cleaner, and more transparent models are achievable. The challenge is not eliminating all compromises, but ensuring they are managed consciously and aligned with broader sustainability goals including the ambitions of the Fit for 55 package.